Advantages of Industrial SLC NAND Flash Cards for Embedded OEM Designs

Flash memory cards come in a variety of form factors and use several different NAND memory types to store data. Each NAND type has its advantages and disadvantages. This post will cover the advantages of SLC NAND in mission critical and Embedded OEM applications where data integrity is paramount.

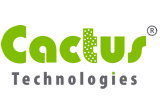

First, let’s look at the three main types of NAND memory in use today. SLC NAND stores one bit per cell, MLC stores two bits per cell and TLC stores three bits per cell. Due to challenges associated with storing more bits per cell, reliability suffers more with MLC and most with TLC versus SLC. The reason MLC and TLC solutions exist is cost and data density – not reliability.

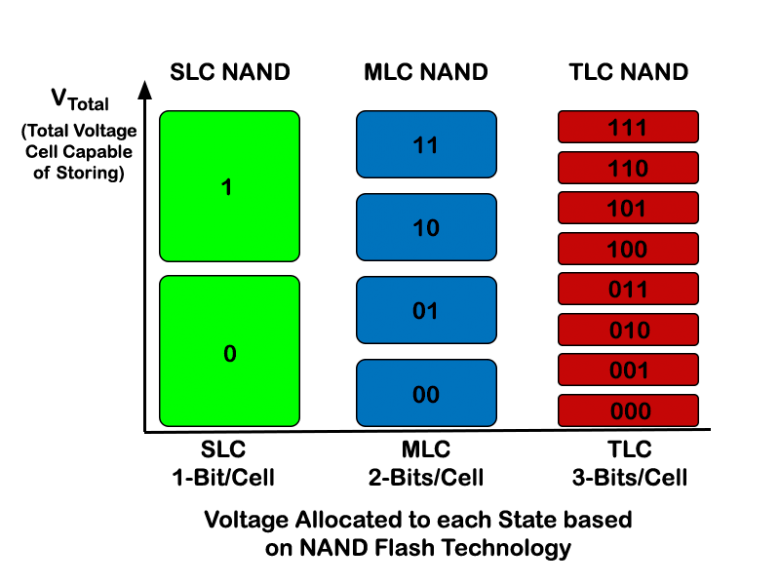

The image below shows key advantages of flash cards based on SLC NAND. These flash cards are also known as Industrial Grade Flash Storage devices. They come in a variety of form factors such as Industrial Grade Compact Flash, Industrial SD Cards, Industrial microSD and others. MLC NAND devices are considered Commercial or Consumer Grade depending on other attributes and TLC devices are almost exclusively Consumer Grade.

The added guard band available to the SLC NAND flash designer allows for greater immunity to temperature extremes and much better endurance cycles. Endurance cycles signifies the number of times a memory block can be erased prior to becoming unusable. SLC is >20 times more reliable than MLC NAND. SLC is >100 times more reliable than TLC NAND which can have as little as 200-300 raw endurance cycles per block.

Another advantage of SLC NAND is the ability to maintain the BOM (Bill-Of-Material) for long periods of time. The BOM is the list of components a flash card is made from. A fixed or locked BOM signifies there are no changes in the manufacture of the flash card. This means the Controller and NAND silicon do not change and the firmware controlling the card does not change either. Industrial Grade cards typically have a locked BOM of greater than 5 years.

Cards based on MLC NAND and TLC NAND generally do not have BOM control. As a lower cost memory or a firmware version is available, it is immediately cut into production to save costs or improve yields. This is great from a cost perspective, but has been known to introduce bugs into a previously working solution and cause compatibility issues with existing OEM designs.

The cost of an SLC Industrial Grade solution is more than that of the MLC and TLC NAND based solutions. This is and will always be the case. It just costs more to manufacture SLC NAND. But, for the most reliable flash storage device available, in many Embedded OEM Flash Storage designs, this is an essential expense.

If you would like to discuss the flash data storage requirement of your embedded OEM design, please contact us.