Advantages of Connector for Embedded OEM Flash Storage Designs

For embedded OEM designers there are several challenges which present themselves. During the design process, many highly regarded features must be dropped as compromises are made.Embedded Flash Storage in the form of a Module can have advantages in this mission.

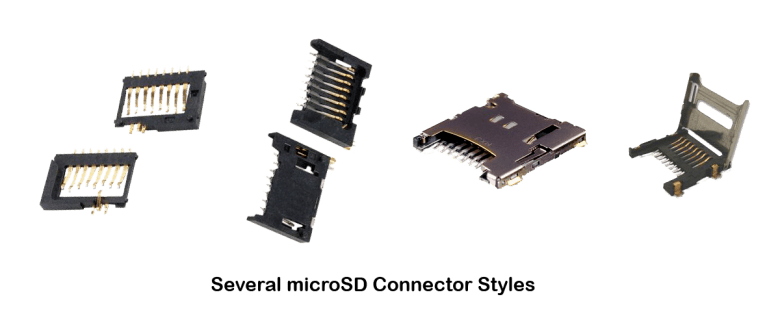

There is a reason for the popularity of industry standard form factors.From early PCMCIA cards to CompactFlash, SD, microSD and now SATA Modules. These flash storage devices allow the manufacturer to put off the decision of memory capacity and type until after the product is built.In some cases the decision is left up to the end user in the case of consumer devices.

An example of an embedded design which would benefit from a flash storage device with a connector would be a Data Logger Device.A base system could be designed with a CompactFlash connector which allows for several different capacity points to be populated depending on customer preference.

To further the example, a 128MB Industrial Compact Flash card could be installed for a low end system.A 2GB - 4GB Industrial CF Card for the mid-range system and a 32GB - 64GB for the high end system. With the large price difference between 128MB and 64GB for Industrial flash storage, this good, better, best strategy allows a single OEM design to meet three different customer requirements.

At a minimum, it would be a good idea to consider modular flash storage devices when contemplating a new embedded OEM design.You may find there are more advantages than you thought.

At Cactus Technologies, we live and breathe flash storage devices for Industrial Embedded applications.If you are an OEM requiring the best supplier for your embedded application, please contact a Cactus Technologies’ Expert.