Solid State Drive Primer # 6 - NAND Architecture - Component Packaging

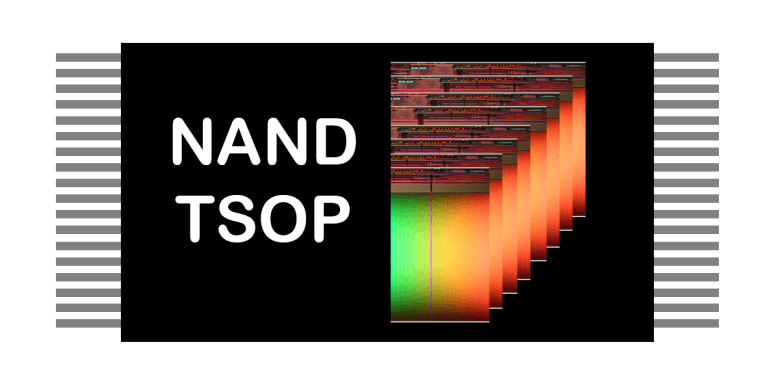

The NAND die themselves are relatively fragile and require special equipment for placement and bonding. Typically NAND die are placed inside a protective component package as opposed to directly on a circuit board. Most follow an open industry standard defined by JEDEC.

These components allow a manufacturer to place a single or several NAND die inside one package with a standard pin-out of typically a TSOP or BGA package. The standard packages are easily handled by the pick and place systems as they adhere the parts to printed circuit boards (PCBs) prior to being run through soldering machines.

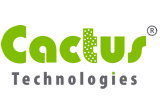

BGA Packaged NAND

There is an insulating layer between each NAND die and connections are made from each NAND die to the substrate using a wire bonding machine. The substrate is like a very thin PCB (Printed Circuit Board) which is the base for the stacked die. As with the single die cutaway shown earlier, the entire top of the component is encapsulated.

If the parts share a JEDEC standard form factor, the parts appear physically identical regardless of the number of die inside.

TSOP Packaged NAND

Future articles will look at putting the NAND components and a controller together to create a Solid State Drive as well as the challenges required of the SSD controller technology.

If you would like to discuss this further please contact us.