SSD Controller and Firmware Key to Locked Bill-Of-Material Strategy

This article talks about the importance of the SSD Controller and the firmware algorithms as they relate to a Locked-BOM (Bill-Of-Material) strategy.

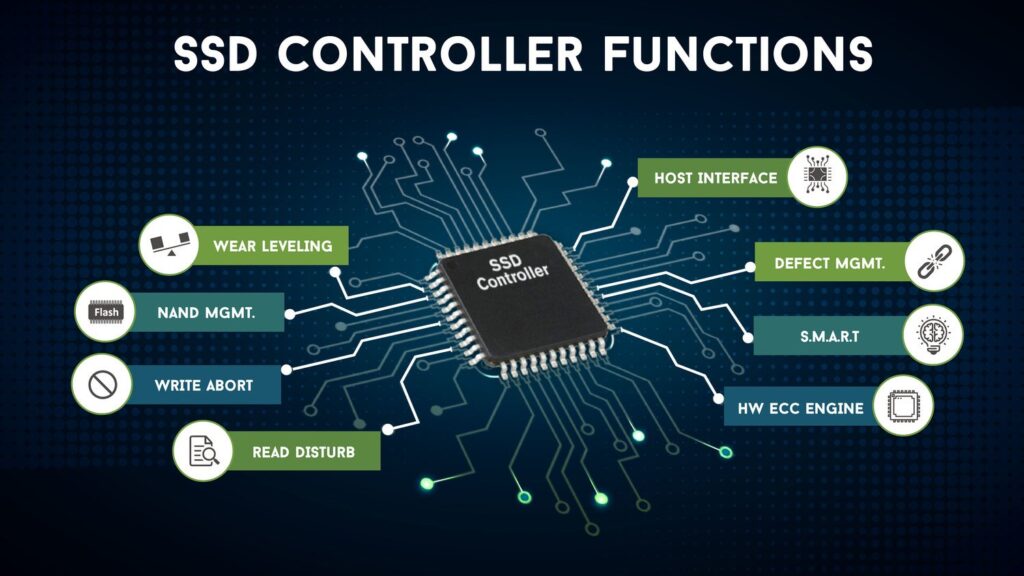

The controller and memory are the two major silicon components of all Solid State Drives. While the NAND memory is the key building block and has finite endurance and data retention, the controller has a major effect on the overall performance, reliability and data integrity of the SSD.

Definition Corner:

-

NAND Flash Endurance - number of times a cell can be erased/written

-

NAND Flash Data Retention - time the data remains stored once written

-

Firmware – code that runs the controller (like the Operating System of the Controller/SSD)

Any changes to the controller or memory silicon can have a profound impact on the functionality, timing or other nuances of the controller’s operation.

The worst part of this is that the vast majority of flash storage devices, SSD, M.2, mSATA, CF, SD Cards, SDChips, etc., are constantly updating their firmware and occasionally revising their silicon.

What is Locked-BOM

Locked-BOM (Bill-Of-Material), aka Controlled-BOM, Fixed-BOM, is when the components of the flash storage device do not change.

What this means is that every manufacturing build of a particular part number flash card is identical. Not only the processes, but the silicon components including the firmware.

It sounds like an easy thing to do.

The Challenge to Locked-BOM

As the memory market continues on a fast paced race to the latest technology for lower costs and improved performance, many memory & controller suppliers regularly “End Of Life” current parts as they migrate to newer generations.

For a memory device manufacturer and in turn their customers who integrate these parts into Industrial and Embedded OEM systems, this should be a major concern.

To lessen the risk associated with changing memory and controller silicon, it is imperative that a flash storage device manufacturer have three key focuses:

- Selecting a Memory/Controller Supplier(s) with a long term focus

- Stocking material as needed to eliminate forced transitions onto their customers

- Integrity to discuss transitions with their customers and not “slip” new designs into production

Why Firmware is Just as Important as the Silicon

The easiest way to show how changes in firmware can have an effect is your latest mobile phone update.

When you update your phone, most of the time you get the advantages of some new feature and/or bug fix. But, every so often, the new code unintentionally disrupts other functions.

This is even more critical for an Industrial or Embedded OEM design where any small change can cause a remote installation to fail without notice.

Most manufacturers of SSD and other flash storage devices change firmware on a regular basis to improve yields and for other reasons.

Cactus does NOT change our Bill-Of-Material without many months of advance notice and the ability to plan a transition up to years in the future. This not only gives peace of mind, but also a level of integrity in the overall system architecture you do not find in other products.

Final Thoughts:

Cactus Technologies focus is to make the most reliable Industrial and Embedded OEM flash storage devices, with locked-BOM, to ensure the identical characteristics over the many years of production.

From Industrial Grade Flash Storage Devices based on SLC NAND memory, to OEM and Industrial MLC products, based on pSLC and MLC NAND memory. All have Extended Temperature range versions, and price points to meet differing application budgets.

Our products come in a wide variety of interfaces to meet needs of embedded OEM application designers everywhere.

If you need assistance with an OEM design or needing special features, please contact us.